Vision System

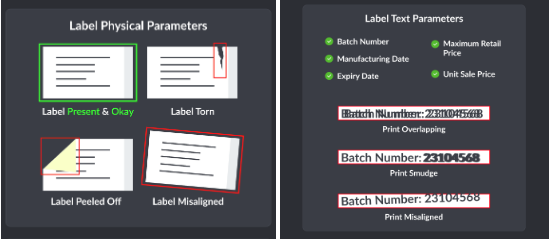

AI4M brings the power of advanced computer vision to factory floors, enabling precise, high-speed, and reliable inspection across industries. Our Vision Systems are built to detect defects, read codes and text (OCR), and identify parts with exceptional accuracy—driving quality, traceability, and operational efficiency.